Product introduction:

Lft-g long glass fiber infiltration production line is to fully impregnate the continuous fiber with molten thermoplastic resin, pull it out into rod or strip through the setting die, and cut it into pellets of different lengths (generally 10mm~25mm). Different from the traditional short fiber reinforced material production line, the fiber length of the long glass fiber reinforced material produced by our LFT-G production line is the same as the length of the cut particles, which can reach the maximum length for injection molding, because the glass fiber does not go through the mixing process of the extruder and will not be cut short by the screw shear action. Through a appropriate injection molding process, the length of the glass fiber in the product can still be maintained at a length of 3~5mm (while the length of the glass fiber in the ordinary short fiber reinforced plastic injection product is generally only 0.2mm~0.7mm). Long glass fiber reinforced plastics have higher impact strength and better rigidity than short fiber reinforced materials. At the same time, the molding shrinkage rate is smaller and the product deformation is smaller.

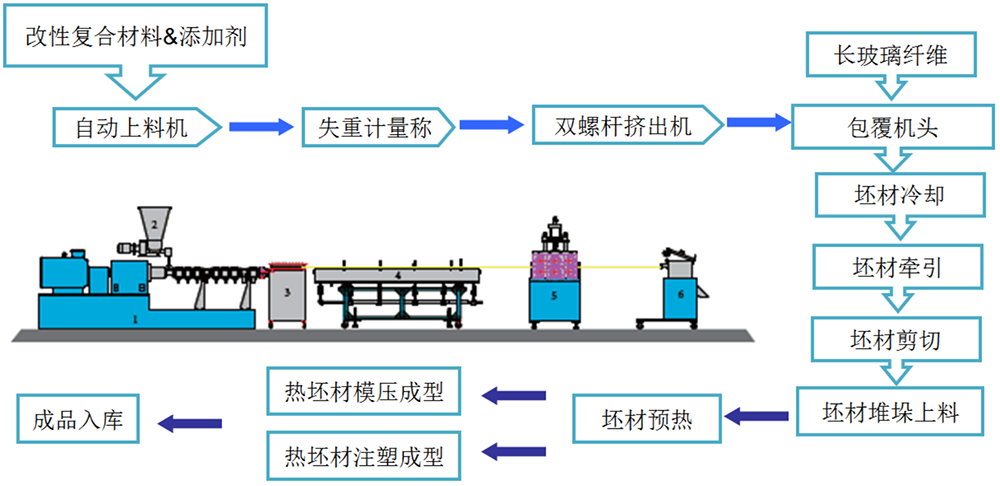

Production process:

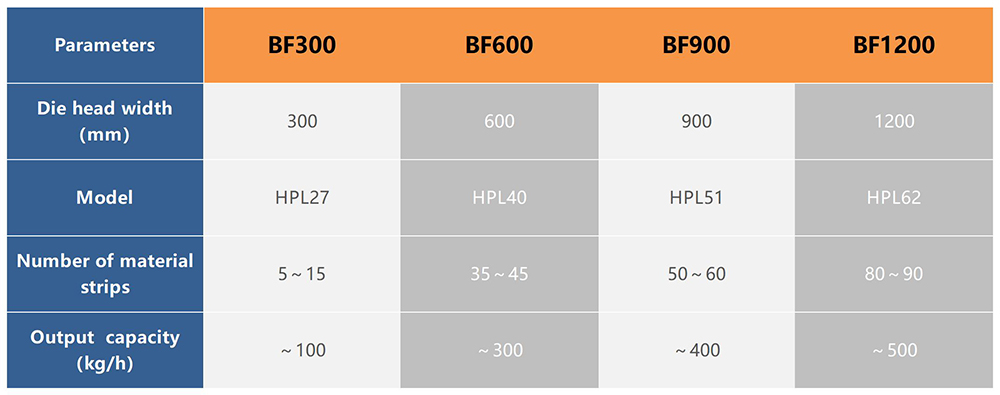

Technical parameters:

Have questions about the product? We are always here to help you

Office phone028-85865728

faxfax028-85861108

company addressNO.4, Jinteng Road,Dujiangyan Economic Development Zone,Sichuan,China

18180485887 (Ms pu)

18030608060 (Mr Zhu)

18583903320 (Mr Xue)

sales@sc-advs.com

qiulin.zhu@sc-advs.com

xuesong@sc-advs.com